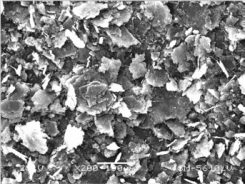

Synthetic graphite is a man-made form of graphite derived by using high-temperature treatment on amorphous carbon materials. Synthetic graphite is processed at ultra-high temperatures (up to degrees to 3,000 degrees), and impurities contained in the precursor carbons are significantly reduced during processing. The carbon content varies widely (typically ranging between 98-99.99%).

1. Primary Synthetic Graphite

Primary synthetic graphite is obtained by transformation of carbonaceous precursor into graphite through an industrial process, called graphitisation (temperature >3000°C).

Graphitisation is a microstructural change which can occur in carbon or low alloy steels that are exposed to elevated temperatures, between approximately 425°C and 600°C, for long periods of time. Simply stated it is the process of converting material into graphite by a heating process.

2. Secondary Synthetic Graphite

Secondary synthetic graphite is also obtained by transformation of carbonaceous precursor into graphite through a graphitisation process.

After crushing, grinding, screening and sieving of the dry raw materials (usually calcined petroleum coke), these are mixed with the tar pitch and moulded in blocks. Blocks are then baked or carbonised at 800-1330°C and graphitised at 2600-3000°C in furnaces.

These blocks are then machined in order to get electrodes of the shapes and sizes required by the metal industry. During this machining process graphite powders are generated. This by-product of the production of graphite electrodes is called secondary synthetic graphite.